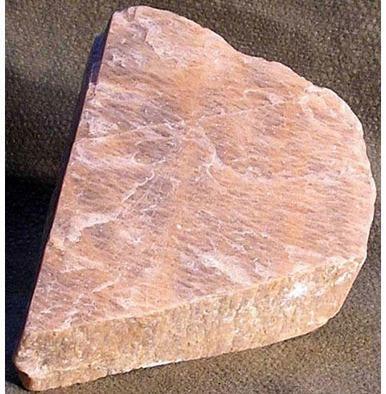

Potash Feldspar

The name of “Feldspar” refers to group of Aluminum Silicate of potassium, sodium and calcium. The chief use of Feldspar mineral is in the Ceramic and Glass Industries. Smaller quantities are used in the manufacturing of Tiles, Whiteware, and Sanitaryware. Other uses of Feldspar include Catalysts, Acid resistant and Decorative Stone as a flux or binding agent in certain scanning Soaps and artificial teeth. Potash Feldspar manufacturer in Rajasthan, Potash Feldspar exporter in Rajasthan, Potash Feldspar exporter in India,Potash Feldspar in India quartz powder in India, Potash Feldspar India, sodium Feldspar India ,albite feldspar India, potassium feldspar india, quartz grains in india

| POTASH-01 | POTASH-02 | ||

| Silica | SiO2 | 66% (+/- 1%) | 68% (+/- 1%) |

| Alumina | Al2O3 | 18% (+/- 0.5%) | 17% (+/- 0.5%) |

| Potassium Oxide | K2O | 12.8% (+/- 1%) | 10% (+/- 1%) |

| Sodium Oxide | Na2O | 2% (+/- 1%) | 3% (+/- 1%) |

| Titanium Oxide | TiO2 | Nil | Nil |

| Calcium Oxide | CaO | Nil | Nil |

| Magnesium Oxide | MgO | Nil | Nil |

| Ferric Oxide | Fe2O3 | 0.06% (+/- 0.01%) | 0.08% (+/- 0.02%) |

| Loss on Ignition | LOI | 0.1% | 0.2% |

* Above are based on our research as well as research of others. However, this document is not contractual and nothing in it constitutes a warranty (expressed or implied) that the goods described are accurate and fit for a particular purpose of the customer. Purchasers are advised to make their own test to determine the suitability. Potash feldspar is used in various industries.